GLASS

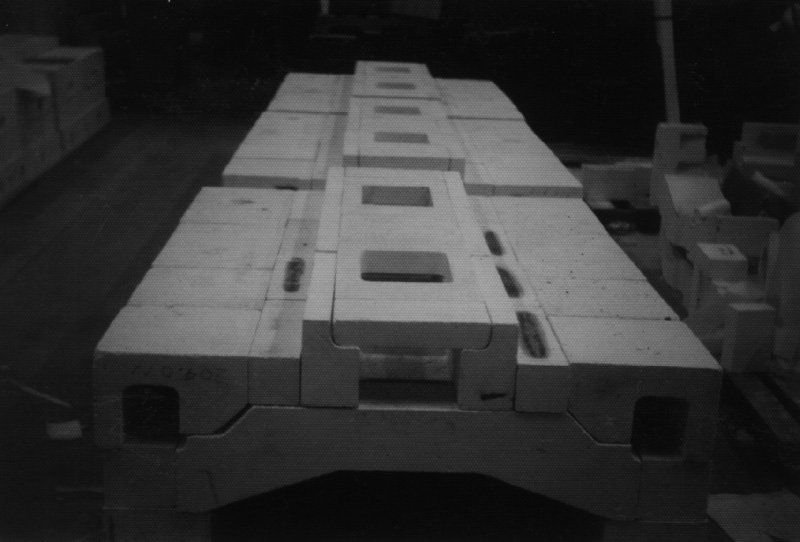

From melting to the gob formation, our highest performance and purity process plays a crucial role in the excellent quality of glass containers.

Our flexibility in the manufacturing process, allows us to create pieces that range from small orifice rings for the Spout to large Cover Blocks for Feeders; Our products can be manufactured with our compositions based on Mullite, AZS (Alumina-Zirconia-Silica), Fused Silica and Zirconium Oxide, all of these for special pieces and for bricks, concrete, mortars and tampers.

Zedmex refractory ceramics are widely used in many different glass container manufacturing companies around the world, and our year over year growth in this industry shows the quality of the Zedmex standard.

Compositions

In addition to having a vast experience (more than 40 years) supplying consumable parts to glass container manufacturers around the world, our compositions are specially designed to provide a long, useful life for the refractory, providing a high thermal shock resistance, erosion and abrasion caused by molten glass.

These compositions are widely recommended for lead, limestone, borosilicate and strontium glass melting furnaces, and others.

ZIRCON OXIDE

Our compositions are specifically designed to provide a long life for our refractories, providing them with a high resistance to:

Corrosion

Erosion

Thermal shock