AEROSPACE

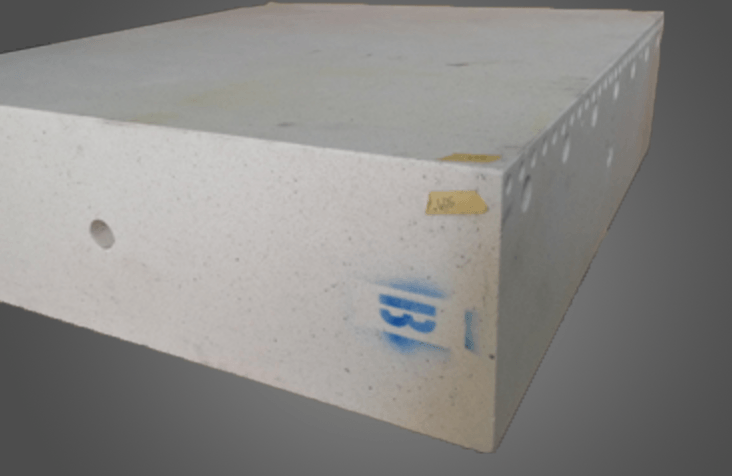

Refractory Zedmex produces the VCFB refractory ceramic platens for the Vacuum Creep Flattening Beds used in the forming of titanium sheet alloys and advanced composites by using a unique fused silica composition.

The state-of-the-art technology for the forming of these shapes and the advanced equipment used by Zedmex have resulted in a ceramic product with extraordinary characteristics known as ZEDSIL IM.

Zedsil IM compositions are used where shape requirements are of a relatively large mass or where superior resistance to compressive loads at very high temperatures are required.

Our fused silica bodies are produced from a very closely grain formulation, specially designed slips and proprietary binders. The shapes demonstrate extraordinary consistency of density with minimal porosity

in even the largest mass castings.

Compositions

The combination of our technology, training, hard work and expertise in the refractory ceramic market for almost 40 years makes Zedmex a reliable and trusted supplier for the aerospace industry.

Main Zedsil IM Properties:

| Chemical analysis: | ||

|---|---|---|

| SiO 2 | min 99:30 | g/cm3 |

| Physical Properties: | ||

| Density | 2.00 - 2.04 | g/cm3 |

| Apparent porosity | 7 - 8 | % |

| Water absorption | 3 - 4 | % |

| MOR @ RT | 1,500 - 1,800 | psi |

| CCS | 10,000 - 12,000 | psi |

| Thermal conductivity @ 500ºC | 0.84 | W/mºC |

| Linear Thermal Expansion @ 1100ºC | 0.6 | cm/cm/ºC x10^-6 |

High resistance to thermal shock

With high thermal conductivity to avoid heat losses in the VCFB process.

Custom made parts for the assembly of leveling beds.