GLASS

From melting to the gob formation, our highest performance and purity process plays a crucial role in the excellent quality of glass containers.

Our flexibility in the manufacturing process, allows us to create pieces that range from small orifice rings for the Spout to large Cover Blocks for Feeders; Our products can be manufactured with our compositions based on Mullite, AZS (Alumina-Zirconia-Silica), Fused Silica and Zirconium Oxide, all of these for special pieces and for bricks, concrete, mortars and tampers.

Zedmex refractory ceramics are widely used in many different glass container manufacturing companies around the world, and our year over year growth in this industry shows the quality of the Zedmex standard.

Products:

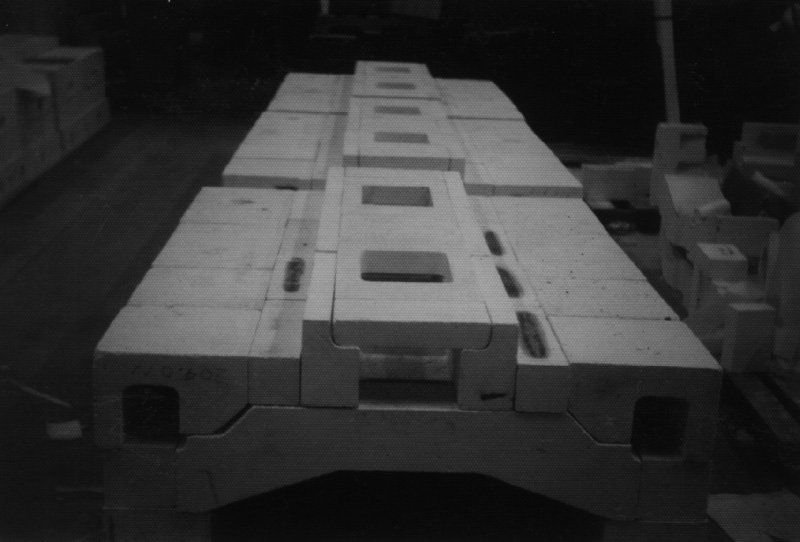

Superstructures

Refractories of the highest quality and purity are essential to obtain a proper conditioning of the molten glass.

For this purpose, Zedmex special refractories for the feeder are designed to provide a longer life to Glass melting furnaces, through extraordinary characteristics such as resistance to thermal shock, abrasion and erosion.

Our wide global experience in supplying specially designed refractories for glass feeders includes pieces for the refiner, alcoves, coloring section, as well as the conditioning and cooling zones.

We keep a wide stock of standard pieces, and unlike other refractory producers, our clients are not forced to adapt themselves to our inventory, instead Zedmex will adapt to their needs, in the right time, and with the right price.

Expendable parts

Zedmex has earned excellent recognition over the years in the refractory industry as a reliable supplier of the highest quality products available globally. Being a flexible manufacturer, and along a team of highly experienced technicians, our mission is to meet the individual requirements of each of our clients, both in their custom pieces and in the type and composition of glass that they handle.

Zedmex offers a wide range of refractory forms, and produces complex pieces for the Glass Feeder Zone in high and low volumes, always keeping a close dimensional tolerance.

Zedmex’s products are formulated with the highest quality raw materials, supplied by globally certified providers, and are designed to reach physical and chemical properties that help prolong production campaigns in the glass feeder, thanks to a high resistance to corrosion, erosion, and thermal shock.

Orifice Rings

We are leading the field in production of orifice rings (bushings), of one to four cavities with standard or special designs.

Plungers

Of all types of tips (Ball, Standard, Flat, Offset, Conical).

Feeder tubes

From 5 ”to 14” in diameter for Feeder, with and without vents, all types of fins or ribs.

Burner Blocks

Spouts

Stirrers

Compositions

In addition to having a vast experience (more than 40 years) supplying consumable parts to glass container manufacturers around the world, our compositions are specially designed to provide a long, useful life for the refractory, providing a high thermal shock resistance, erosion and abrasion caused by molten glass.

These compositions are widely recommended for lead, limestone, borosilicate and strontium glass melting furnaces, and others.

ZIRCON OXIDE

Our compositions are specifically designed to provide a long life for our refractories, providing them with a high resistance to:

Corrosion

Erosion

Thermal shock

All rights reserved Zedmex - Privacy Policy